REFRIGERATOR (SINGLE DOOR)

SINGLE-DOOR REFRIGERATOR: COMPONENTS & WORKING

1. Construction & Working of Key Components

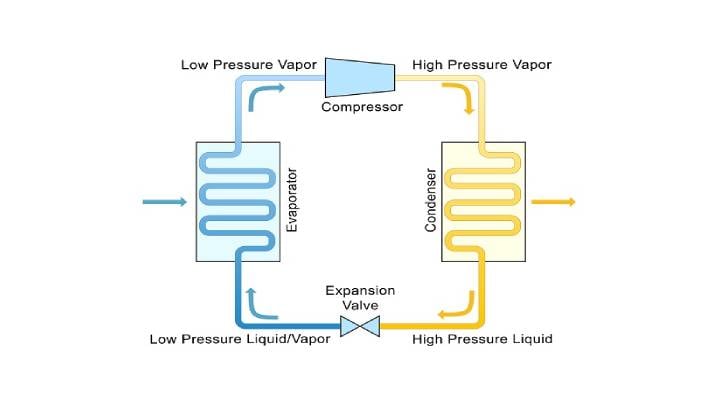

(A) Compressor

- The heart of the refrigeration system.

- In single-door refrigerators, typically hermetic reciprocating compressors are used.

- Working:

- Compresses the low-pressure refrigerant vapor.

- Increases its pressure and temperature.

- Sends it to the condenser for heat rejection.

(B) Condenser

- A heat exchanger that removes heat from the refrigerant.

- Types:

- Wire-and-tube type (found at the back of refrigerators).

- Plate type (mounted on the body of the refrigerator).

- Working:

- Converts hot refrigerant vapor into a high-pressure liquid.

- Heat is rejected to the surrounding air.

(C) Capillary Tube

- A thin, long tube that acts as an expansion device.

- Functions:

- Reduces refrigerant pressure.

- Controls the flow of refrigerant to the evaporator.

(D) Evaporator

- Located inside the freezer compartment.

- Working:

- Absorbs heat from stored food.

- Converts liquid refrigerant into low-pressure vapor.

- Refrigerant then returns to the compressor.

(E) Suction Line Heat Exchanger

- Some models use a heat exchanger between the suction line and capillary tube.

- Function:

- Improves cooling efficiency by subcooling the refrigerant.

- Prevents liquid refrigerant from reaching the compressor.

(F) Door & Gaskets

- Door:

- Made of metal or plastic with insulation.

- Gaskets (Rubber Seals):

- Prevent warm air leakage.

- Ensure proper sealing to maintain cooling.

(G) Heat Insulation Materials

- Polyurethane foam (PUF) is commonly used.

- Ensures minimum heat transfer and energy efficiency.

2. Electrical Components

(A) Thermostat

- Controls the temperature by switching the compressor ON/OFF.

- Adjustable knob inside the fridge.

(B) Relay & Overload Protector

- Relay: Provides starting torque to the compressor.

- Overload Protector: Prevents overheating of the compressor.

(C) Defrost Heater & Timer

- Some single-door refrigerators have manual defrosting.

- Automatic defrosting models use a heater and timer.

(D) Interior Light & Door Switch

- Turns ON when the door opens.

3. Flushing, Capillary & Drier Replacement

(A) Flushing Evaporator & Condenser

- Removes dirt, moisture, and impurities.

- Uses refrigerant gas or solvent flushing method.

(B) Replacing Capillary & Drier

- The capillary tube and drier must be replaced when:

- System is clogged due to moisture or oil.

- Capillary tube is damaged (causing improper cooling).

- Drier absorbs excess moisture, reducing efficiency.

4. Evacuation, Leak Testing & Gas Charging

(A) Evacuation (Vacuum Process)

- Removes air and moisture using a vacuum pump.

(B) Leak Testing

- Done using:

- Soap bubble method (for visible leaks).

- Nitrogen pressure test (for precise detection).

(C) Gas Charging Methods

- Refrigerant charging process:

- Weighing method (most accurate).

- Pressure gauge method.

5. Refrigerants Used in Single-Door Refrigerators

Common Refrigerants & Properties

| Refrigerant | Type | Common Uses |

|---|---|---|

| R-12 | CFC | Older refrigerators (Banned) |

| R-134a | HFC | Most common in older models |

| R-600a | Hydrocarbon | Newer eco-friendly refrigerators |

| R-290 | Hydrocarbon | High-efficiency models |

- Compressor compresses refrigerant gas.

- Condenser releases heat to surroundings.

- Capillary tube regulates refrigerant flow.

- Evaporator absorbs heat from food.

- Flushing & leak testing improve performance.

- Gas charging & proper evacuation ensure cooling efficiency.

- Eco-friendly refrigerants like R-600a are replacing older CFCs and HFCs.